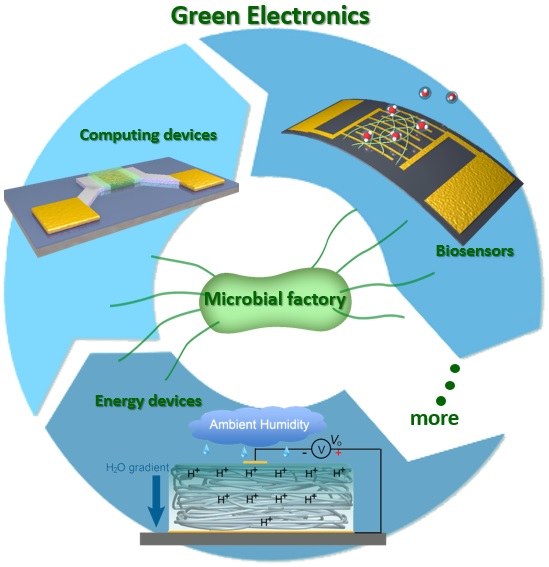

‘Green’ electronics by ‘borrowing’ materials from biosystems.

Conventional electronic systems differ from biosystems in terms of material composition, charge species, computing architecture, etc. Making electronics from biosynthetic materials may not only narrow the gap for closer bio-emulated systems and bio-intimate interfaces, but also discover new/improved functions.

Protein nanowires synthesized by microbe (e.g., Geobacter sulfurreducens) serve as nanoscale ‘cables’ for them to do charge/information exchange with environments. They are electrically conductive and produced from renewable feedstock, generating a new ‘green’ electronic material. Our lab has been developing ‘green’ electronics made from these protein nanowires.

For example, we have discovered that they can be used to make energy device (‘Air-gen’) that continuously harvests electricity from the ambient humidity (Nature 578, 550–554 (2020)), leading to the potential of new green energy technology. A video explaining ‘Air-gen’ technology can be found here:

We have also discovered that the protein nanowires can be used to construct computing device (memristor) that works at the biological amplitude (e.g., ≤100 mV) (Nature Commun. 11, 1861 (2020)), enabling the potential of direct ‘talk’ between electronics and biosystems. They can be employed to construct ultralow-power microsystems that can be directly powered by ‘Air-gen’ to achieve energy self-sustainability or self-autonomy (Nature Commun. 12, 3351 (2021)), like that in a living system. Protein nanowires can be also used to construct bioelectronic sensors; their ultrasmall diameter, high-density surface groups, and intrinsic flexibility can lead to ultrahigh sensitivity (Nano Research 13, 1479 (2020)) and flexible wearable monitoring (Adv. Electron. Mater. 6, 2000721 (2020)). The biofilm (containing the bacterial cell bodies) can be used to convert water evaporation into electricity (Nature Commun. 13, 4369 (2022)).

We hope that more discoveries or new functions will be found along the way. In a long run, we are seeking the potential of employing microbial factory to make materials for electronics.

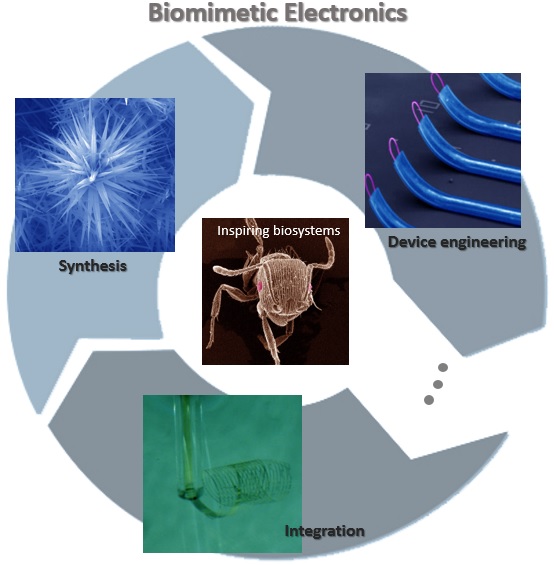

Biomimetic electronics by ‘borrowing’ designs from biosystems.

Biosystems are characterized by the smartness and efficiency in energy conversion, sensory transduction, signal processing, material actuation, etc. Therefore, they are a powerful source of inspiration for smart engineering.

We are very interested in ‘borrowing’ material and structural designs in biological structures/organelles to improve electronic or bioelectronic engineering. The efforts cover from material synthesis, assembly, device fabrication to integration. For example, electromechanical sensor made from nanomaterial that has structural mimicry to tactile hair (i.e., the mechanosensory organelle) in insects can achieve ultrahigh sensitivity for wearable detection (Nature Commun. 9, 5161 (2018)); 3D structural engineering in nanowire structures as an emulation to bioreceptor may improve the sensitivity (Nano Lett. 19, 5647 (2019); Nano Lett. 16, 2644 (2016)), which, for the first time, can work as nanoelectronic sensors that can simultaneously measure the electrical and mechanical activities in cells (Science Adv. 8, eabn2485 (2022)); macroporously integrated mesh electronic scaffold that mimics tissue structure can improve tissue interfacing (Nano Lett. 17, 5836 (2017)). We are looking forward to new opportunities at the boundary of electronics-bio fields: we learn from biosystems for better engineering, which may also feedback to a better electro-bio interfacing.